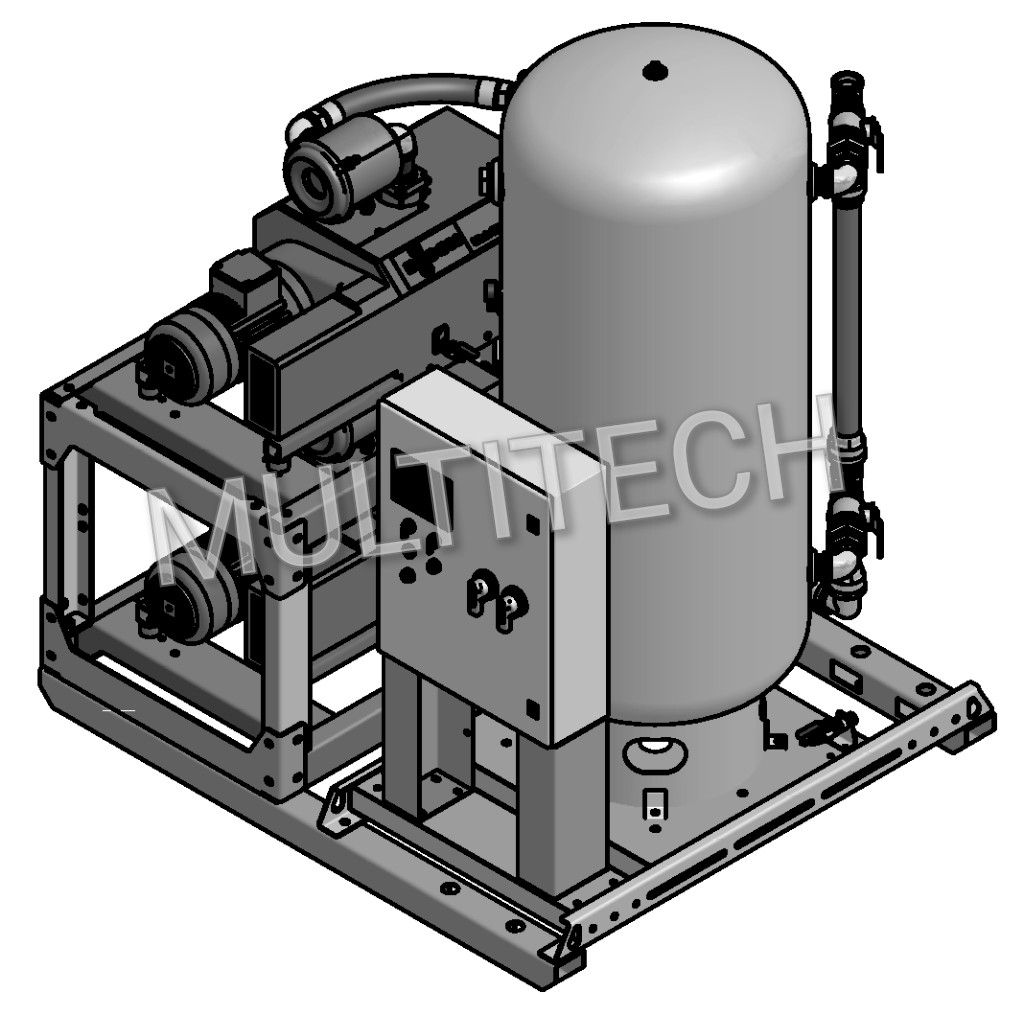

VACCUM SYSTEM As per NFPA99 latest edition/ HTM-2022/02-01 /EN/DIN/ISO 7396-1 Oil Sealed Rotary Vane Medical Vacuum System Vacuum system shall be total capacity ( running + stand by ) 14000 LPM at 19” Hg to be delivered to the hospital with necessary requirement of relevant International Standard The Oil Lubricated Rotary Vane Medical vacuum System will provided superior performance with minimal maintenance. The packaged system will contain all necessary controls and components to meet or exceed NFPA99C-2005 recommended guidelines. Systems will be available in simplex and all multiplex arrangements. The factory packaged vacuum system consists of rotary vane vacuum pumps, pre-wired control panel, receiver, and interconnecting wiring and piping, requiring only two plumbing connections. The Medical Vacuum systems will be available as base mounted with a vertical receiver. The vacuum pumps will be continuous duty, rotary vane, oil-sealed, air cooled, direct driven units capable of continuous operation over a working range of 18” to 29” Hg. Each pump will have single shaft seals and will be equipped with an automatic gas ballast valve to prevent condensation of water vapor, extending the life of the oil and the system. The pump will include an integral, multi-stage oil-removal system featuring a built-in exhaust demister that will remove and reclaim 99.9% of the exhausted oil. Additionally each pump will include an exhaust back pressure gauge to indicate the need for filter maintenance and an oil sight glass for monitoring oil level. Lubrication will be provided by the integral, fully recirculating oil supply. The pump inlet will be protected by means of a wire mesh screen. An internal anti-suckback valve will be included to prevent oil from entering the vacuum piping network. Pump vanes, because of their construction, will provide superior heat transfer and long life. The pumps will be dynamically balanced and virtually vibration free. Each pump will be driven by a direct flanged three-phase, standard TEFC motor via a pin and bush coupling. The pump will operate at 83 dBa,. Pumps require standard automotive garde SAE-30 non-detergent oil for lubrication.

VACCUM SYSTEM As per NFPA99 latest edition/ HTM-2022/02-01 /EN/DIN/ISO 7396-1 Oil Sealed Rotary Vane Medical Vacuum System Vacuum system shall be total capacity ( running + stand by ) 14000 LPM at 19” Hg to be delivered to the hospital with necessary requirement of relevant International Standard The Oil Lubricated Rotary Vane Medical vacuum System will provided superior performance with minimal maintenance. The packaged system will contain all necessary controls and components to meet or exceed NFPA99C-2005 recommended guidelines. Systems will be available in simplex and all multiplex arrangements. The factory packaged vacuum system consists of rotary vane vacuum pumps, pre-wired control panel, receiver, and interconnecting wiring and piping, requiring only two plumbing connections. The Medical Vacuum systems will be available as base mounted with a vertical receiver. The vacuum pumps will be continuous duty, rotary vane, oil-sealed, air cooled, direct driven units capable of continuous operation over a working range of 18” to 29” Hg. Each pump will have single shaft seals and will be equipped with an automatic gas ballast valve to prevent condensation of water vapor, extending the life of the oil and the system. The pump will include an integral, multi-stage oil-removal system featuring a built-in exhaust demister that will remove and reclaim 99.9% of the exhausted oil. Additionally each pump will include an exhaust back pressure gauge to indicate the need for filter maintenance and an oil sight glass for monitoring oil level. Lubrication will be provided by the integral, fully recirculating oil supply. The pump inlet will be protected by means of a wire mesh screen. An internal anti-suckback valve will be included to prevent oil from entering the vacuum piping network. Pump vanes, because of their construction, will provide superior heat transfer and long life. The pumps will be dynamically balanced and virtually vibration free. Each pump will be driven by a direct flanged three-phase, standard TEFC motor via a pin and bush coupling. The pump will operate at 83 dBa,. Pumps require standard automotive garde SAE-30 non-detergent oil for lubrication.

The standard electrical control panel includes the following components: Integral circuit breaker disconnected with door interlock, across-the-line motor starters with three phase overload protection A programmable logic controller to cycle lead pump with each use Hand off Automatic selector switch for each pump. Lag pump in use indicator light with horn and connection for remote annunciation. Hour meters to monitor factory recommended service intervals. Pump running lights to indicate pump in operation.

Each system will include an ASME coded receiver rated for full vacuum service. The system receiver will include a 4-1/2” vacuum gauge, manual drain, and three- valve bypass. Additionally, each system will include properly sized inlet and exhaust flex connectors and vibration isolation pads for field installation. The vertical receiver will be internally lined with an FDA approved material for corrosion resistance. The pump has the facility that in case one pump stops the standby pump will automatically start. if any pump fails the system will automatically revert to the stand by pump. All the status monitoring of the pump can be connected to the Master Alarm.

The system will also include factory installed 5 micron pump inlet filters as per NFPA-Guidelines to promote longer life. The system is supplied with silencer and bacterial filters.