The medical vacuum pumps are used to provide the vacuum required by the hospitals. Generally in large hospitals use vacuum for various medical applications. The various manufacturers design, engineer, and develop various types of medical vacuum pumps. The design of the medical vacuum pumps is efficient and has low maintenance cost. The hospitals need the high level of reliability in case of medical vacuum pumps. The medical vacuum pumps constantly monitors the vacuum pressure in the system. These pumps produce less noise and heat into the equipped room, creating an ideal working environment. The vacuum pumps are used in various businesses such as dental and medical practices.

The medical vacuum pumps are used to provide the vacuum required by the hospitals. Generally in large hospitals use vacuum for various medical applications. The various manufacturers design, engineer, and develop various types of medical vacuum pumps. The design of the medical vacuum pumps is efficient and has low maintenance cost. The hospitals need the high level of reliability in case of medical vacuum pumps. The medical vacuum pumps constantly monitors the vacuum pressure in the system. These pumps produce less noise and heat into the equipped room, creating an ideal working environment. The vacuum pumps are used in various businesses such as dental and medical practices.

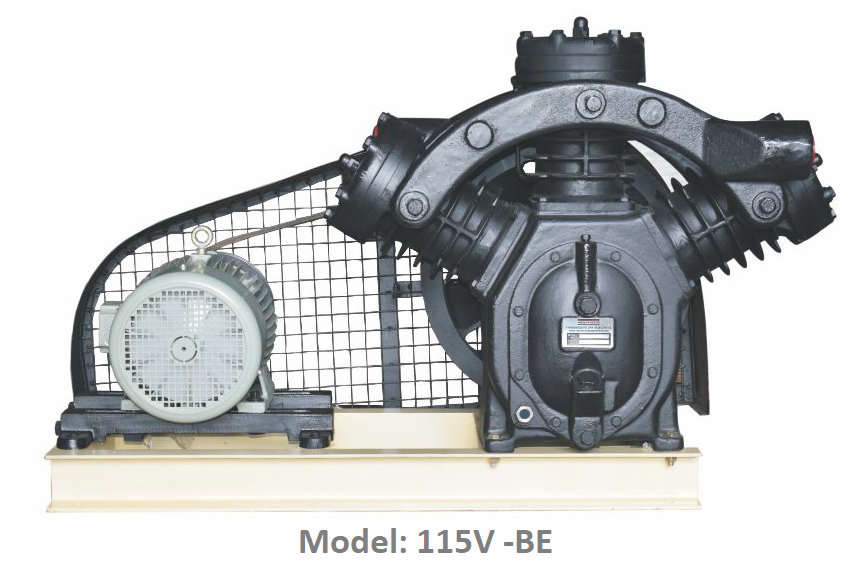

Reciprocating piston dry vacuum pumps are a type of vacuum pump that uses pistons to create a vacuum. These pumps are oil-free, making them ideal for applications where oil contamination is not acceptable.

Reciprocating piston dry vacuum pumps are a type of vacuum pump that uses pistons to create a vacuum. These pumps are oil-free, making them ideal for applications where oil contamination is not acceptable.

Reciprocating piston dry vacuum pumps are also relatively quiet and vibration-free, making them well-suited for use in laboratories, clean rooms, and other sensitive environments. They are available in a variety of sizes and capacities and are typically used for applications such as vacuum packing, laboratory vacuuming, and industrial degassing.

One of the key features that set reciprocating piston dry vacuum pumps apart is their oil-free operation. Unlike traditional oil-sealed pumps, these pumps do not require any lubrication with oil, making them ideal for applications where a clean and oil-free vacuum is essential. This feature prevents any risk of oil contamination in the process, ensuring a contaminant-free environment.

Rotary vane vacuum pumps are a type of positive displacement pump that uses a rotating rotor with vanes to create a vacuum. The vanes are positioned inside slots in the rotor, and as the rotor rotates, they are thrown out by centrifugal force and slide against the inner surface of the pump housing. This creates a series of chambers that are alternately filled and emptied with gas. As the gas is pumped out, the pressure in the chamber decreases, creating a vacuum.

Rotary vane vacuum pumps are a type of positive displacement pump that uses a rotating rotor with vanes to create a vacuum. The vanes are positioned inside slots in the rotor, and as the rotor rotates, they are thrown out by centrifugal force and slide against the inner surface of the pump housing. This creates a series of chambers that are alternately filled and emptied with gas. As the gas is pumped out, the pressure in the chamber decreases, creating a vacuum.

Rotary vane vacuum pumps are a versatile type of pump that can be used for a wide range of applications. They are typically used in applications where high flow rates and moderate vacuum levels are required. Some common applications for rotary vane vacuum pumps include vacuum packaging, laboratory vacuuming, industrial degassing, food processing, semiconductor manufacturing, and medical devices.

The industrial vacuum pumps help in making the manufacturing of products cleaner, smarter, economical, and bio-friendly. Various manufacturers provide unique and innovative solutions in the form of industrial vacuum pumps for semiconductor production. Some of the applications of industrial vacuum pumps are rotary vane pumps, centralized vacuum pumps, and many more. Some of the advantages of industrial vacuum pumps are highest performance, robust, reliable, and economical. Many manufacturers produce the industrial vacuum pumps for various specific needs such as for chemical, petrochemical, food, and pharmaceutical industries. Some industrial vacuum pumps are also used in dry-running applications with gas and gas-air liquid transfers.

The industrial vacuum pumps help in making the manufacturing of products cleaner, smarter, economical, and bio-friendly. Various manufacturers provide unique and innovative solutions in the form of industrial vacuum pumps for semiconductor production. Some of the applications of industrial vacuum pumps are rotary vane pumps, centralized vacuum pumps, and many more. Some of the advantages of industrial vacuum pumps are highest performance, robust, reliable, and economical. Many manufacturers produce the industrial vacuum pumps for various specific needs such as for chemical, petrochemical, food, and pharmaceutical industries. Some industrial vacuum pumps are also used in dry-running applications with gas and gas-air liquid transfers.